sika

Sika Shushtar ceramic and pottery factories with the aim of creating a knowledge-based ceramic complex, relying on the technical and academic ability of the company’s members who have brilliant scientific and practical experience (more than three decades) in the ceramic industry in 1387 Shushtar city has been registered.

Objectives of Sika factories

One of the most important goals of the company is to diversify the production of modern products in the ceramic industry by relying on the latest technology and avoiding the repetition of the usual products of the ceramic market. With the selection of the site for the construction of the complex located in Shushtar city, with the allocation of land by the Land and Housing Organization in 1397, with an area of 46,000 square meters for the machinery and building sector, as well as 20,000 square meters for the mining factory, after that, the implementation of the project, including the following sections, began became:

Excavation of uneven ground

Leveling and wall painting

Construction and installation of 10,000 square meters of industrial sheds (height: 8-14 and 27 meters in two openings of 20 and 25 meters)

Construction of security building and VIP lobby

Construction of guest house and office building

The selection of machines has been done with specialized technical reviews and the plan is ready for credit opening and entry of phase one machines.

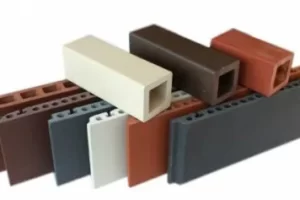

The company’s products, including slab tiles and large-sized perforated clay panels, will be offered for the first time in Iran and the region. They will be described in detail in the following lines.

Sika Ceramic and Pottery Industries Co

It is the first producer and leader in the ceramic industry and all kinds of porcelain panels and perforated pottery (Hawadeh) by EXTRUSION method in Iran, and is one of the priority and specialized projects in the construction industry in Khuzestan province (Shoshtar region), which is more than 2500 years old. It is with brick and mud buildings.

Due to the increase in global demand for ceramic and quasi-ceramic products, SIKA company is trying with all its facilities to continuously update the production systems, from the processing and preparation of materials to the production, color and coating and optimized thermal treatment, with benefits. Taking the most modern machines of the production lines, a very beautiful product with a reassuring quality and satisfied by customers to meet all the demands of creating beauty by creative young architects, construction industry engineers, mass builders, housing builders, trustees and design and program managers. It provided urban planning, urban planning engineers, mayors and decision-making managers of urban and rural areas, etc.

The production lines and machines have been selected in such a way that by using dry micronized powder technology to produce a fully optimized product to reduce energy (about 65% in the production process and about 50% in use) in optimizing the role of energy and reducing weight by 30% They will have the building.

Compliance with environmental principles is one of the requirements in the production process and products of this company, and all the products of this collection are designed for recovery and optimization.

Facade functions and effective factors in facade construction

The most basic and even in terms of age, the first task that Nama was responsible for was protection. In order to protect themselves from weather and climatic factors, humans created a space called house for themselves. The absence of openings in the building prevented wind, rain, heat and cold, but deprived the building of the necessary light and ventilation. As the need for these gifts increased, the need to create an opening in the wall of the building increased, and as a result, the need for another shell called facade for more protection arose.

The facade of the building as a protection must have the following technical characteristics:

Insulation against cold and heat

Different building materials have different heat transfer coefficient and specific heat capacity and as a result they will have different thermal performance. A successful facade system is a facade that has both beauty and energy efficiency. Having a facade that has a good thermal performance directly affects energy consumption, therefore, the use of materials with a lower thermal transfer coefficient should be considered in the facade of the building.

Sound insulation

The facade of the building can act as an ideal sound insulation. Paying attention to this feature is especially important for buildings located in large industrial and commercial cities or next to the main thoroughfare.

- Earthquake resistance

- Impact resistance

- Resistance to freezing (zero water absorption)

- Fire resistance

- Resistance to falling and wind speed

- Flexibility in the execution of the view

- The facade is light, beautiful and in accordance with the customs, culture and civilization of each region

- It can be used in high-rise buildings and create trust and traffic safety

The facade of the building should be designed in such a way that despite the protection of the inside environment from the outside, it establishes the connection between the outside space and the inside environment of the building well. For example, it is possible to shine light inside or to use the view outside.

Just as a person’s clothes represent his personality, the house should also represent the character and social status of its owner, just like the second clothes. In the western architecture, it has a mode of display, so that it shows the person who lives behind it in the first place. In fact, the facade represents the family character and social class of the owner. In addition to introducing the personality of the owner, the facade represents the location of the property and the type of use of the building and the culture, civilization, history, architecture, religion and climate of that region.

We are not facing a single building in the urban space, in fact every building is a part of the urban space whose ugliness affects the public spaces and its beauty depends on the harmony with other elements of that place. The building is not an isolated and self-sufficient entity that can attract all the attention of the designer and owner, but it should be an element of a unified society while maintaining its personality and credibility.

The facade is the external appearance of every building and it is not a hidden cover away from public expectations. The facade is always in the public’s attention, so beauty is an integral part of every facade. Also, the beauty and quality of the facade represents the art and quality of the work of architects, engineers and building designers.

The appearance of each building is different depending on environmental conditions such as weather, wind and storm, earthquake and the amount of air pollutants in different areas. The materials used in the facades of large and industrial cities that have high pollution are different compared to the materials used for the facades of small cities that have clean air. Also, the facade of the building in cold regions is different from the usable facade in tropical regions in terms of the degree of resistance against freezing or insulation against cold and heat.

One of the most important factors in choosing a facade is its price. As the price of facade increases, purchasing power will decrease and the circle of consumers of that facade will be more limited.

Due to the fact that prolonging the operation of any construction project can increase costs and decrease the value of money, therefore, speed in the implementation of facades will be very effective.

Ceramic facade

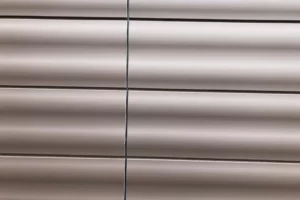

Due to the high price of stone and the load that stone imposes on the building, the use of ceramic for the facade of the building in some countries has gained considerable popularity. Ceramic façade has solved the problem of weight up to a quarter of the weight of stone, but the problem of connection between ceramic and facade has not been solved except in a few cases, and there is an attempt to solve the problem of connection between facade components by using installation methods. Due to the controllable design, these views can present their own beauty to the viewer. Among the disadvantages of ceramic facades is its lack of insulation against cold, heat and sound. Also, ceramic facades are not used in crowded places due to their glazing and strong light reflection. (According to the fact that the production of advanced facade parts is done with an extruder forming system, there is the ability to produce flexible products with different geometric and non-geometric shapes. However, in the ceramic industry, this ability is limited by the method of vertical hydraulic presses. )

Brick facade, panels and porcelain plaques (perforated and non-perforated) Ventilated and Terracotta

One of the most common and most popular facades are brick, clay and porcelain facades with large dimensions by forming and producing by extrusion and vertical presses, which include clay bricks and shale bricks and porous and non-perforated porcelain with feldspar and There are various kaolins and other additives. In addition to the beauty, diversity, color stability and naturalness (made of soil), the facades mentioned above play the role of a thermal and cold insulation for the building due to their low heat transfer coefficient and as a result of energy wastage by the heating and cooling system. They prevent the building. According to its material and color, brick facades repel and reflect heat in the summer season and absorb solar energy and heat the building in the winter season. Sika Company is the first producer of these products in the country.

dry view

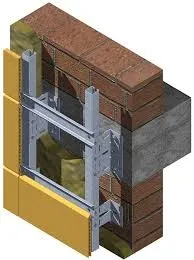

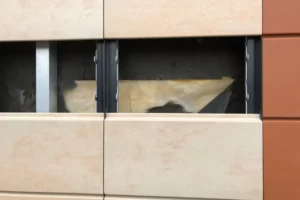

In the dry facade system, mortar is not used to connect the panels to each other. To connect the special bricks that are used in this system, metal equipment such as rails are used, which plays an essential and vital role in building style.

Advantages of dry facade system with clay panels

In the dry facade system, the installation of panels and rails is only mechanical, so the implementation of this system with engineering calculations and executive detail drawings does not require a professional worker.

The implementation of this system is much faster and easier in the high parts of the building than in other facades due to the lack of mortar. Also, in this system, there is access for periodic maintenance, especially in high buildings.

In the installation of dry facade, due to the use of metal frames, which are considered as the template and model for the facade, and the lack of mortar and the risk of falling of non-standard materials, the lightness of the material that can be installed on the floors, the speed of the facade is significantly increased.

With the passage of time and the advancement of technology in the construction industry, time plays a very important role in this industry, and the methods designed and proposed by construction experts have all been evaluated with important standards, and it can be said that they have been preserved by evaluating this important factor. Is. With a little thought, we realize that the dry facade execution method can reduce up to 50% of the execution time and even bring the negative effects of the ambient temperature to zero, and due to the lack of mortar and traditional methods, with the possibility of using several work groups simultaneously in the departments The upstream and downstream of the work increased the speed of the work and of course other things such as the use of trained groups instead of traditional and non-technical forces lacking the necessary knowledge in the old and traditional methods as well as the use of industrial tools and machines in doing the work. In modern methods, despite the significant impact they will have on execution time and preventing possible duplication of work, it will definitely increase the quality and type of execution. Of course, one of the other advantages of the dry facade implementation method, which has a great impact on the completion time of the projects, is the possibility of starting the facade work with a short time interval after the completion of the building skeleton.

The dry facade system can be applied directly on the wall without removing the existing wall surface, and therefore, the implementation of this system is without creating waste and usual construction waste, as well as without creating noise.

According to the technical and engineering design of the facade, including the infrastructure and the precise design of the desired dimensions and plaques for each project, according to the openings, building height, usage and other influential factors, and the possibility of ordering panels and consumables accurately, while reducing the implementation time difference, the impact It will greatly affect the quality and quantity of performance.

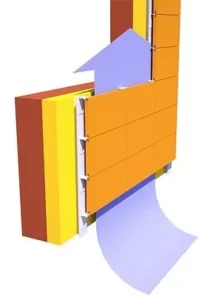

In the dry facade system, first a thermal insulation is independently fixed to the building body with a mechanical connection or glue, then the supporting frame or skeleton, which is made of wood, steel or aluminum, is connected to the building until the dry facade is kept at a distance from the thermal insulation on Place the supporting frame. The empty space between the facade and insulation is the best thermal insulation, so this system plays a significant role in reducing energy loss.

It has been consecutive years that the execution of the facade inside and outside the building is done by people without the necessary training with traditional materials such as: sand and cement mortar, which in addition to overloading the building, which due to the importance of buildings being resistant to the strong force of earthquakes and The direct relationship between the lateral force of the earthquake and the weight of the buildings, due to the difference in the heat transfer coefficient and also the difference in the expansion and contraction of the mortar behind the stone or ceramic, etc., compared to the external materials of the facade and the existing stiffening part, is observed that with A little time has passed, the stones have been separated and even the wire scoops do not prevent it from falling, and it has caused a lot of life and damage.

With the industrial production of facade substructure sections including: iron, aluminum or galvanized and steel profiles as well as facade materials, the possibility of human error will be seriously reduced, especially in parts such as: the percentage of mortar mixing, etc., and therefore the impact It will greatly increase the quality.

Another problem that is usually seen in traditional systems is the formation of non-level cracks that occur after grouting due to the movement of stones etc. Dry execution, because hardening materials (mortar) are not used in the execution, it is possible to adjust the possible errors even in millimeter during the execution and even after the work is finished, and even years after use, it is also possible Moving and modifying individual panels or ceramics, etc. is ready.

It is very important to pay attention to the fact that normal facades definitely need repair, reconstruction and re-installation after a few years, and this in itself means imposing an additional cost that the employer must bear for the facade after some time, and finally, considering the useful life of the works. A grout that is about 10 to 15 years old must destroy the entire layer of mortar as well as the corresponding stone, and this means that if money is spent on grout facades after the completion of the building work, it should be considered completely damaged.

A reduction of about 80 to 100 kilograms of weight per square meter of the implemented facade compared to the grouting method, which will have a great effect on reducing the destructive force of an earthquake. And if at the beginning of the building design work, the facade is seen as dry, with a significant reduction in the weight of the building, not only the finished price does not increase, but also by reducing the weight of the skeleton and foundation, it leaves a significant reducing effect on the finished price.

Nowadays, the beauty and type of design of building facades shows the work rank, type of activity and even the mindset, ideas and points of view of owners, builders, design engineers, architects, and managers of companies and organizations.

Therefore, these attitudes have caused the approach of managers and experts to install modern facades in a dry method with air conditioning, which in the meantime has given a special beauty to the facades of buildings by using various materials.

Up-to-date façade systems, which were designed and used for tall towers by dry stone installation in the 1970s for the first time in the United States, were one of the new methods in accordance with the new construction standards, which were used in the 1970s in Iran. It was implemented that significant progress has been made in this field during the past years until today.

Therefore, in the implementation of dry facades, due to the installation of the industrial method, with the passage of time, there is no need for repair and maintenance costs, and if this type of facade is damaged, each of the plaques can be repaired and replaced, and there is no need for destruction or general modification. And even after its useful life (more than 50 years) it is possible to recycle all the used materials, including the base metals (iron or aluminum) and most importantly the used panel or ceramic, and each of these materials can be recycled in places and other places according to the type of use, and this means that all the costs incurred for the implementation of this facade will be returned to the employer after the completion of the construction work, in terms of the standard percentage of the depreciation of the materials.

Due to the modernization of all parts of life in this century and the involvement of all people in this matter, as well as the sense of aesthetics and the human tendency towards beauty, the science of architecture and building design has undergone a rapid transformation during the last years of the 20th century. and it is moving towards industrialization, which obviously has received a great influence on the facade of buildings, which has been one of the axes of creating and developing all dry and modern methods in facade construction.